For many Plant Managers and Engineers, selecting the right-sized industrial air compressor can be a challenging task. Compressed air is an energy source that is rarely measured or tracked in existing industrial facilities, so reliable data on this subject is often unavailable. Frequently, this information must be cobbled together from the stories and anecdotes of plant personnel. While these observations are well-intentioned, they usually provide little benefit to an engineer that is sizing a new air compressor.

When designing and building a brand-new facility, selecting the right-sized industrial air compressor can be even more daunting. Without an existing baseline from which to start, engineers must meticulously tally the air demand of every pneumatic component to be installed, apply a usage factor for the expected duty cycle, and hope the end result is an accurate representation of reality.

Both of these scenarios are fraught with uncertainty, and many engineers intentionally “pad” their estimates to avoid selecting a compressor that is too small. This often leads to the installation of oversized and improperly selected air compressors.

It has been a huge problem in Texas where a business needed only 50hp, but someone says ‘I’m just going to buy 100hp because it will be more than I need.’ But, that is a really bad idea because the machine will run at half-capacity all the time. That is not the way a machine is designed to run. It will use more power than a 50 horsepower running at 100% capacity.

BRAD BONNECASE, SULLAIR OF HOUSTON

In spite of these uncertainties, there is good news for folks tasked with selecting and purchasing a new industrial air compressor. By carefully considering the following questions, engineers can increase the likelihood they will choose the right-sized unit for their next project.

HOW WILL THE COMPRESSED AIR BE USED?

As with any industrial system, the end-use application is the most important factor in determining air compressor sizing. Each application is different and carries a unique set of considerations.

Some applications require a steady, predictable supply of compressed air with little variation (e.g.- process air for chemical manufacturing). In these scenarios, it is usually best to install a compressor with a full load capacity that closely matches actual air usage. Little consideration for part-load efficiency is needed, and extra capacity is not required. The best strategy, in this case, is to achieve optimal performance at full load, and ensure the process is never under-supplied with compressed air.

By contrast, other applications require highly variant supplies of compressed air. These processes need air compressors that can fully support the largest anticipated demand, but also operate efficiently in part-load conditions. For example, an industrial machine shop might have several machining centers that are used at different times. Air usage will depend on which combination of machines is utilized for a particular job. In these scenarios, compressors with an efficient part-load operation are often beneficial. In some cases, the installation of multiple compressors for staggered operation is a viable approach.

WHAT ARE THE EXPECTED AMBIENT CONDITIONS?

Ambient conditions are always an important factor in industrial air compressor sizing and selection. Not only do equipment sub-components need to be rated for operation in the expected conditions, but air compressor output capacity is also affected. In high heat, ambient air is less dense because its molecules are farther apart from each other. As such, an air compressor must work harder in order to deliver the same output as compared to colder temperatures. Likewise, high humidity also reduces air compressor capacity. Water molecules displace air molecules on humid days, so compressors must intake a greater volume of ambient air to produce the same output.

Consideration must be given to these factors when selecting a new compressor. The full load capacity of an industrial air compressor can be reduced by 10% or more due to high heat and humidity. Engineers must pay careful attention to ensure they size new compressors for the worst-case conditions expected at the site.

ARE THERE ANY INTERMITTENT DEMANDS?

Applications that use compressed air are often divided into two primary categories. Dynamic applications require a steady supply of compressed air at all times. A common example of a dynamic application is a sandblast cabinet. When the sandblast nozzle is engaged, an uninterrupted supply of compressed air is needed. The only acceptable interruption of this flow occurs when the operator releases the nozzle trigger.

Conversely, intermittent applications require a fixed burst of compressed for a short time, with a break between cycles that allows the system to recover. An example of an intermittent application is a pneumatic cylinder that actuates periodically. A fixed volume of compressed air is required to push the piston through its stroke, but no other compressed air is needed until the next cycle.

When sizing a new air compressor, engineers should be aware of how each compressed air application fits into these categories. Often, intermittent demands can be supplemented by installing air receiver tanks at the point-of-use. This strategy can sometimes reduce the amount of required compressor horsepower. Talk to a trusted and competent compressed air professional for more information on employing air receivers to supplement intermittent demands.

WHAT IS THE COMPRESSED AIR QUALITY REQUIREMENT?

Some critical applications require the compressed air supply to be extremely dry and free of contaminants. In these instances, regenerative dryers must be utilized to achieve ultra-low dew points in the compressed air stream.

While regenerative dryers are useful for this purpose, they reduce the overall volume of compressed air that is available for the application. When sizing a new industrial air compressor, engineers must incorporate regenerative dryer purge losses into their demand estimates to ensure an adequate volume of air is supplied at the point-of-use.

When designing a compressed air system, start from the point-of-use and move backward from there. First, determine the flow, pressure, and air quality that is required at the application. Many folks try to pick the air compressor first…but, the best strategy is to start at the end, then add up all of the variables (such as demand, dryer purge losses, and leaks) before selecting an air compressor that can handle the job.

Steve Mahaffey, HOLT Industrial Systems

WRAPPING UP…

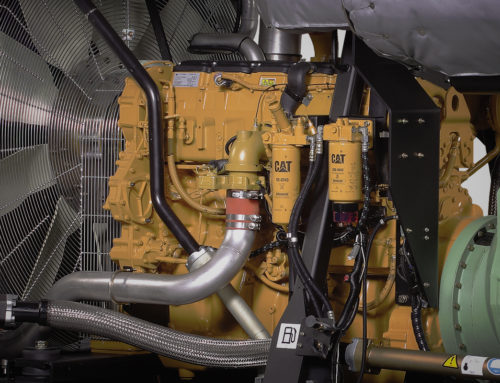

Though the general concepts of mechanically-compressed air have been around for hundreds of years, in recent years, industrial air compressor technology has evolved rapidly in order to keep up with constantly changing demands and needs for compressed air.

Thus, searching for the right industrial air compressor system with the right size for your facility or your next job can be tricky. But now you’re equipped with the tools and knowledge necessary to make an educated decision on which compressor is a perfect fit for your business.